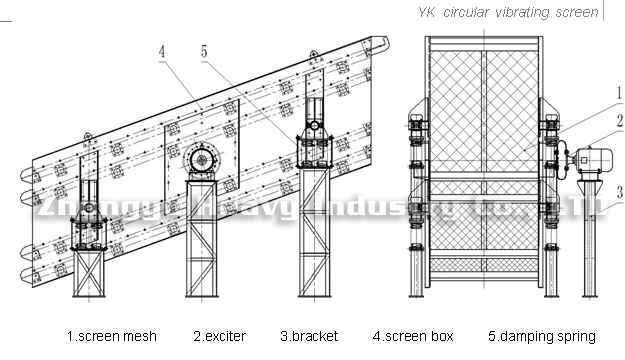

Circular vibrating screen is named after its cyclo-motion trail. as a new type screening equipment, it features adjustable amplitude, long screening line, multiple layers, distinct specifications for each layer and high screening efficiency. Circular vibrating screen is quite suitable to be applied in mining, coal, ore beneficiation and other related industries. While during its working, parameters often affect its working efficiency.

1.

Types of screen deck: steel bar, steel wire, punching steel plate, tire, flexane are normally seen in the market. Their influences to screen efficiency mainly reflect in effective area; besides, rub proofness of various materials are also diverse.

2.

Shape of sieve mesh: square or rectangle sieve mesh are mostly used

3.

Size of sieve mesh: should be chosen according to

crusher types and requirement of products

4.

Moving condition of griddle: screening efficiency of diverse griddles are as follows: 90% for high-efficiency heavy duty screen; 70%-80% for shaker screen; 60% for drum screen; 50%-60% for fixed bar screen. Choose by your own requirement

5.

Width and length of griddle: general-used length-width ratio is from 1:2.5 to 1:3

6.

Slant angle of sieve surface: angle is general from 0 degree to 20 degree, but fixed bar screen is between 40 degree and 50 degree.