-

Crushing Equipment

- Impact crusher PCL vertical impact crusher PLF Sand making machine Jaw crusher

- Sand making machine Heavy hammer crusher

Feeding particle size: 210mm-1020mm

Handling capacity: ≤800T/H

Features and Benefits

1, Low noise, fewer dust, high crushing ratio.

2, Large adjusting range of discharge gate

3, Deep crushing cavity with no dead zone, easier to feed materials and yield higher output.

4, Safe and reliable lubricating system makes it easier to replace components, less maintenance.

5, High strenghened magnese steel, features in abrasion resistant, compression resistance, long service time

Working principle:

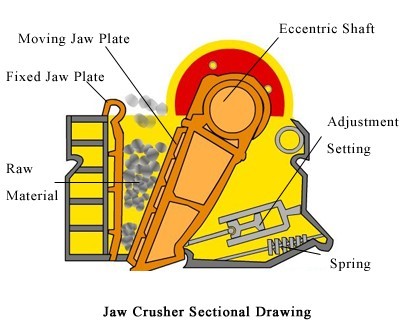

The upper of movable jaw is hanged directive on the eccentric shaft to act as the connecting rod of crank link mechanism

and driven directive by the eccentricity. The bottom of movable jaw is propped up to the back of rack by being hinged with the

thrust plate. When eccentric shaft revolves, the track motion of each point on movable jaw gradually turns from circumference

of pendent point down to ellipse, the lower the point, the more partial the ellipse, until the track of connection between bottom

point and thrust plate comes to circular arc.

Copyright©2010-2011 Zhongyu Heavy Industry Co., LTD