-

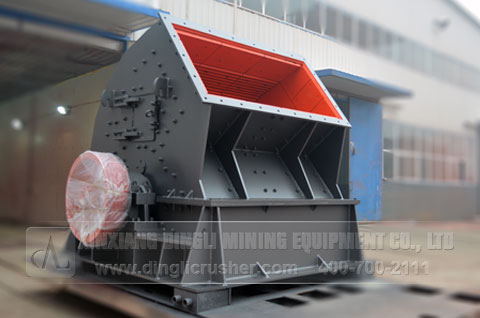

Crushing Equipment

- Impact crusher PCL vertical impact crusher PLF Sand making machine Jaw crusher

- Sand making machine Heavy hammer crusher

Hammer crusher is the core and important machine in mining industry and gravel production line. Upon the common problems in operation, we will analysis you the cause of vibratory.

1. Large machine gap

Hammer crusher is a huge crushing machine working with rotor, bearing parts, and bearing rings. Larger gap between rotor and bearing, bearing ring and base will cause machine vibrating.

2. Rotor bending

Hammer crusher can crush medium hardness material by hitting and crushing for required material size. However, rotor spindle as the main force bearing parts has easy breaking condition than other parts.

3. Rotor spindle operating speed

The rotating speed of rotor has great influence on machine stable operation. Reaction force is related to angle speed and lager angle speed will change machine spindle, small angle speed will influence production efficiency. Thus, it is important to change and adjust rotating spindle angle.

4. Uneven rotor spindle force

Uneven spindle force will be the main cause of hammer crusher vibrating. Material is fed into crusher chamber and crushed by rotor. So, uneven rotor spindle will cause machine vibrating.

5. Hammerhead quality

Hammerhead quality decides its structure, strength, abrading condition, and then influences its vibrating condition.

These are the reasons of hammer crusher vibrating. If you have these questions in machine, please check our website of www.dinglicrusher.com.

Copyright©2010-2011 Zhongyu Heavy Industry Co., LTD